RELATED Handling & Sterilizing PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

When customers need more than products simply moved from point A to point B, ProMach’s Handling solutions can accumulate, position, feed, orient, flip, stack, load, unload, distribute, rotate, reject, push, divert, index, and perform numerous other intricate product handling challenges. And when customers need to deliver shelf stable products to the marketplace, ProMach’s Sterilizing solutions span the entire range of retort technologies, from entry-level systems to entire automated retort rooms. ProMach backs these solutions with cellular line integration and engineering services to automate entire portions of production lines to achieve optimal performance.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

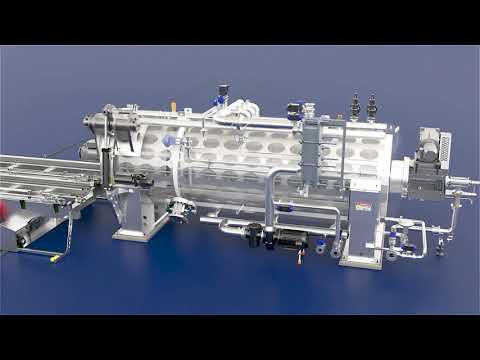

learn moreSteam Air Retorts Features

- All stainless steel construction: 304 or 316

- Up to 72" / 1800mm diameter

- Lengths up to 4 baskets/positions (rotary) and 8 baskets/positions (static)

- Swing-open or space-saving overhead orbiting doors

- Available with the Allpax Monitor control system -fully 21 CFR Part 11 validation ready

- Also available with Gentle Motion capability

- Dual-axis rotary clamping mechamism

- Severe-duty modular trunnion rollers

- Preheated air injection