ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

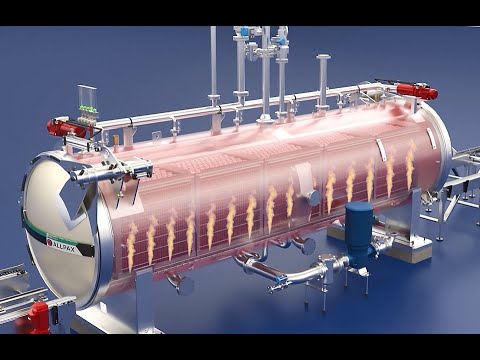

learn moreSaturated Steam Retorts Features

- Carbon Steel construction or All stainless steel construction: 304 or 316

- From 24" / 610mm to 72" / 1800mm diameter

- Lengths from 1 basket to 8 baskets

- Swing-open or space-saving overhead orbiting doors

- Available with the Allpax Monitor control system -fully 21 CFR Part 11 validation ready

- Also available with Gentle Motion capability

Food Autoclave

Allpax provides processing and sterilization machinery with industry leading controls to fully automate the retort process for virtually any container. When your products require autoclaves, allow Allpax to meet your industry needs.

With a complete range of severe duty sterilization and material handling machinery including the food autoclave and lab autoclaves for various industries, you’ll notice a drastic difference in manufacturing and production lines. Designed for numerous industries, the machinery from Allpax works to keep your products clean, sterile and ready for consumers.

If you are in the food industry, the food autoclave is the perfect addition to your product line. Incorporating high pressures and temperatures, your products are left sterile and clean for the next stage of production. Don’t risk faulty machinery in your production lines. Using the food autoclave, you can create the perfect environment for the safety of your products and the health of your customers.

The lab autoclaves are also available to a number of industries. When your product specifications require the use of an autoclave, Allpax has a variety of products to meet your exact needs. Allpax provides fully automated retort rooms, individual retort room components, and turnkey equipment. Becoming one of the world’s leading sterilization solution providers, when you need lab autoclaves for your production lines and retort rooms, there are several machines to choose from.

Allpax provides production retorts for the use several industries. When you’re looking for maximum process efficiency, consider the Steam Retorts, Water Immersion Retorts, Food Autoclave, Steam-Air Retorts, Spray Retorts, Lab Autoclaves, or the Production Shaka Retorts 1300 and 1600. Each machine from Allpax is designed by engineers and specialists in the field of thermal processing of low-acid foods in cans, pouches, jars, and bowls. When you’re products require the use of a food autoclave, the machines offered at Allpax are designed for even temperature distribution and are available with various types of agitation to deliver optimal come-up times.

The lab autoclaves from Allpax are designed with precision and innovative technology. Working hard to get your products ready for shipping and distribution, there are several R&D retorts available. Choose from the Gentle Motion Retorts, Shaka Retorts, 5202 Multimode R&D Retort, 3802 Multimode R&D Retort, and the 2402 Multimode R&D Retort. Each of the lab autoclaves from Allpax ensures customers a safe and clean process for sterilization.

Allpax wants each industry to find use and satisfaction from the food autoclave, retort packaging products, and lab autoclaves. Ensuring that the each production retort, each food autoclave, and all of the lab autoclaves are working properly to meet your industry requirements is of the highest priority. When you’re looking for equipment that provides your products with safety, sterilization, and cleanliness, Allpax has a variety of options.

Find the best autoclave for your industry and enjoy precision in each use. While each food autoclave works to ensure that the food industry has the best equipment available, the lab autoclaves work hard for a variety of other industries.

Allpax steam recovery systems generate significant energy savings and help the environment by cutting plant emissions.