ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreProduction Agitating Retorts

Allpax offers production agitating retorts that provide complete turnkey retort solutions with flexibility needed to accommodate diverse applications. The production retort machines that we offer are designed for even temperature distribution and are available with various types of agitation to deliver optimal come-up times.

The production retorts that are offered are designed by engineers and specialists in the field of thermal processing of low-acid foods in:

- Cans

- Pouches

- Jars

- Bowls

With any questions and to learn more about the production agitating retorts, contact Allpax via our contact form or by calling us today.

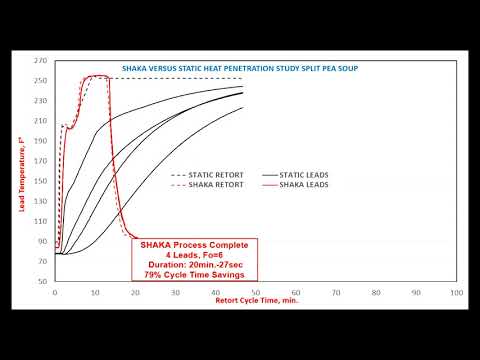

The new Allpax Production Agitating Shaka retort is the latest in the Allpax line of agitating retorts. The production capacity Shaka retort allows for a full-size basket of product to be run.

Offering a compact mechanical design, improved convection heating, a reduced cycle time in heating and cooling phases, and eliminated product surface burning. This system is specifically designed by Allpax.

Allpax is the leader in designing and manufacturing custom automated retortable beverage lines using the latest technologies in commercial batch processing.

The Shaka process provides improvements in production with dramatic cycle time reduction and increased throughput. Improved product quality and better nutrient retention are afforded through reduced thermal burden with rapid heating and cooling steps.