ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreProduction Agitating Shaka Retort - Flexibility Demonstration

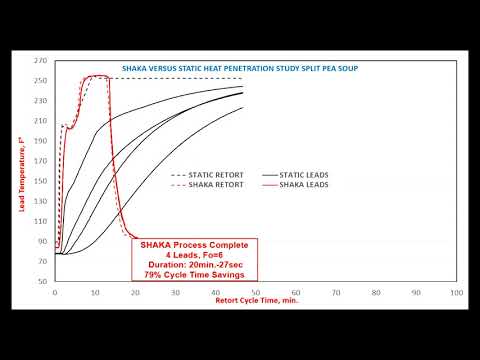

Production agitating shaka retorts are designed by engineers and specialists in the field of thermal processing of low-acid foods in cans, pouches, jars and bowls. The production retort machines that we offer are designed for even temperature distribution and are available with various types of agitation to deliver optimal come-up times.

The production agitating shaka retort offers a new dimension of shelf stable products and up to 90 percent cycle time savings. Using this machine benefits products by enhancing their taste, texture, and color as well as improving the nutritional value.

This production shaka retort only requires 2.24KW to maintain speed and features batch product flexibility, an automated retort loading option, an automated product clamping option, minimal retort stress or vibration, a conservative robust design, and will process rigid, semi-rigid, and flexible containers.