Allpax Showcases Processing Innovations for Ready-to-Drink Beverage Production at Pack Expo

Sep 27, 2022

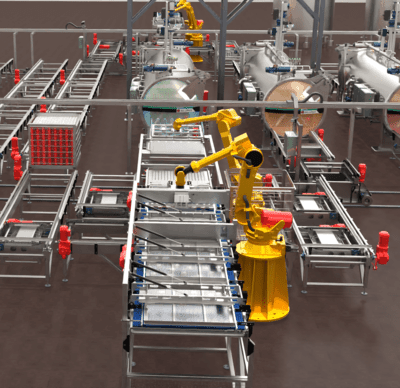

COVINGTON, LA — Allpax, a ProMach brand, features retort and retort room automation solutions for the ready-to-drink (RTD) beverage industry at Pack Expo 2022. Allpax joins more than a dozen ProMach brands in a multi-exhibit “Canning Solutions” showcase illustrating the one-stop-shop advantages of selecting ProMach as the primary equipment supplier for canned beverages, offering machinery and systems for blending & processing, container conveying and accumulation, filling & sealing, retorting, labeling, coding, bundling, case palletizing, stretch wrapping, etc., plus world-class turn-key engineering and system integration capabilities. Pack Expo, Oct. 23-26, McCormick Place, Chicago, Allpax Booth # N-5350.

When Allpax refers to the canning of RTD beverages, it is in the broadest sense of the term ‘canning’ which includes the handling of multiple different types of packaging formats from aluminum cans to glass and plastic bottles to flexible stand-up and spouted pouches. Allpax retorts and retort room automation equipment processes shelf-stable low-acid drinks such as milk-based coffee, tea, and energy drinks packaged in the various containers mentioned above.

The in-booth demo at Pack Expo focuses on Allpax’s world-leading Model 2402 Multimode R&D Retort that helps research institutions and processors alike bring new shelf-stable foods and beverages to market more quickly, and with higher levels of quality. The Multimode R&D Retort is controlled by the same software as Allpax’ production retorts, thus supporting fast and accurate scale up from lab to production. The 2402 will demonstrate rotary agitation, which in conjunction with the integrated hotwell tank greatly reduces sterilization and cooling times. Reducing product heat exposure through faster processing results in higher throughput and better tasting shelf stable RTD beverages.

Allpax’s sole business focus is on the retort room. Allpax is the only retort system supplier in North America that designs, manufactures, builds, assembles, fully tests, and supports its installed base of production retort equipment. Allpax controls, including hardware and software, are FDA compliant. The company has more retort installations serving the RTD industry than any other supplier in North America.

All the equipment and systems Allpax sells can be remotely connected to via the internet, thus facilitating 24/7 remote support for fast and effective problem resolution. All replacement parts and pre- and post-support services are available directly through Allpax. This ensures that components are of the highest quality, and that qualified and experienced engineers and technicians are available to work on the equipment.

Visit Allpax Booth #N-5350 at Pack Expo to discover how Allpax expertise and its sole focus on retorts and retort room automation can help bring your products to market faster, and ensure higher throughput, efficiency and consistent product quality. Visit www.allpax.com for the company’s full line of products and services.

About ProMach

ProMach is a family of best-in-class packaging solution brands serving manufacturers of all sizes and geographies in the food, beverage, pharmaceutical, personal care, and household and industrial goods industries. ProMach brands operate across the entire packaging spectrum: filling and capping, flexibles, pharma, product handling, labeling and coding, and end of line. ProMach also provides Performance Services, including integrated solutions, design/build, engineering services, and productivity software to optimize packaging line design and deliver maximum uptime.

ProMach designs, manufactures, integrates, and supports the most sophisticated and advanced packaging solutions in the global marketplace. Its diverse customer base, from Fortune 500 companies to smaller, privately held businesses worldwide, depends on reliable, flexible, technologically advanced equipment and integrated solutions. ProMach is headquartered near Cincinnati, Ohio, with manufacturing facilities and offices throughout the United States, Canada, Mexico, Brazil, Europe, United Arab Emirates, and China. For more information about ProMach, visit www.ProMachBuilt.com.

About Allpax

Supporting the highest levels of product safety and regulatory compliance, Allpax manufactures processing and sterilization solutions for the food, beverage, pet food, pharmaceutical, and nutraceutical industries, including autoclaves, retort room components, fully automated retort rooms, and product handling equipment that supports retort room automation. Allpax is a product brand of ProMach, a global leader in packaging line solutions. As part of the ProMach Product Handling business line, Allpax helps our packaging customers protect and grow the reputation and trust of their consumers. ProMach is performance, and the proof is in every package. Learn more about Allpax at www.Allpax.com and more about ProMach at ProMachBuilt.com.

Media Contact

David Starck | David.Starck@promachbuilt.com← Back to Press Releases